High-Pressure Hydrogen Materials Synthesis and Testing

Category

Synthesis

Description

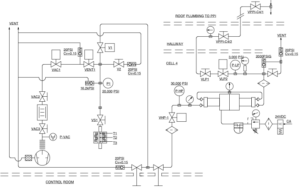

For hydrogen fuel cell applications, high-pressure hydrogen is used to charge the system’s high-pressure tanks that store the hydrogen for fuel cell use. In case a reversible hydrogen storage material (e.g., metal hydride or sorbent) is used to store hydrogen, the elevated pressure causes the uptake of hydrogen by the spent storage material for future consumption by the fuel cell. In some cases, high-pressure hydrogen can be used to synthesize a new hydrogen storage material that is unobtainable by other means. The HyMARC team maintains state-of-the-art high-pressure hydrogen synthesis and testing facilities to address fundamental questions about the physic-chemical behavior of hydrogen storage materials when exposed to various gases at pressures from 0.1 MPa to greater than 10 MPa. The cornerstone of this capability is the high-pressure system at Sandia National Laboratories in Livermore, California, which can achieve pressures of inert gas and hydrogen (or deuterium) of up to 1,000 bar (100 MPa) at temperatures from -78˚C to 400°C. The sample holder can be loaded in a glovebox for air-sensitive samples and can accommodate several separate samples at a time, allowing for the simultaneous exposure of different materials to the same conditions. It is also compatible with commercial Sieverts and PCT equipment, allowing for high-pressure cycling tests without any change in pressure vessel. The system is readily modifiable to add up to two more sample holders and heating stages, as well as calibrated volumes for high-pressure isotherms, further expanding its utility. This setup can easily reach the standard hydrogen storage pressures of 35 and 70 MPa (350 and 700 bar) to study material properties after being subjected to these pressures. Samples are routinely examined by Synchrotron X-ray and neutron diffraction and spectroscopic techniques, as well as in-laboratory FTIR, XRD, and NMR.

This U.S. national resource for testing of hydrogen storage materials in high-pressure gaseous environment includes a range of specialized assets for evaluating materials performance:

- Sorbent Stability: Sorbent materials (e.g., metal-organic frameworks, covalent-organic frameworks, carbons, zeolites) can be exposed to high-pressure gaseous helium and hydrogen (up to 10 MPa) over the range of -78˚C to 400˚C, with subsequent evaluation of structural changes, chemical decomposition, and possible pore collapse.

- Metal Hydride Reversibility: Various materials (e.g., metals, metal hydrides, borides, nitrides) can be subjected to constant pressures of hydrogen or deuterium (up to 100 MPa) at various temperatures (up to 400˚C), with subsequent assessment of the material’s gravimetric and volumetric hydrogen storage density, cycle-life, and plateau pressure.

- Hydrogen Reaction Mechanisms: Isotope-exchange studies in the high-pressure facility allow the exposure of hydrogenated specimens to gaseous deuterium under isothermal conditions over a wide range of pressures, thereby investigating hydrogen dissociation phenomena. Material properties measured include H/D ratio, chemical composition, and crystal structure.

Status

Synthesis and testing capabilities are on-line and fully functional.

Figures

References

- J. L. White, N. A. Strange, J. D. Sugar, J. L. Snider, A. Schneermann, A. S. Lipton, M. F. Toney, M. D. Allendorf, V. Stavila, "Melting of Magnesium Borohydride Under High Hydrogen Pressure: Thermodynamic Stability and Effects of Nanoconfinement," Chem. Mater. 2020, 32, 13, 5604–5615.

- V. Stavila, L. Klebanoff, "Nanostructured Metal Amides and Nitrides for Hydrogen Storage, " US Patent Application 62/235,930, November 2015.

- R. Newhouse, V. Stavila, S. J. Hwang, L. E. Klebanoff, J. J. Zhang, "Reversibility and Improved Hydrogen Release of Magnesium Borohydride, " Journal of Physical Chemistry C 114 (2010): 5224–5232.